In modern manufacturing and engineering, materials play a pivotal role in defining performance, efficiency, and sustainability. Over the past decade, there’s been a noticeable shift towards lightweight metals that can deliver both structural strength and design flexibility. Industries ranging from automotive to aerospace are driving this transformation, and the trend is only accelerating as technology advances and environmental pressures grow.

The evolution of lightweight design

The demand for efficiency has sparked an evolution in how manufacturers approach product design. Reducing material weight is not only about saving costs but also about improving overall system performance. In transportation, for example, lighter materials can lead to better fuel economy and lower emissions. In construction, they enable faster assembly times and simplified logistics. The continuous development of alloys and precision fabrication methods has made it possible to achieve strength-to-weight ratios once thought impossible.

Meeting sustainability goals

As industries aim to reduce their carbon footprint, the importance of recyclable materials has never been higher. Metal recycling has long been a cornerstone of sustainability, but the shift toward high-strength, lightweight materials enhances this further. Many metals today can be reused without compromising integrity, reducing waste and the need for raw material extraction. This shift aligns perfectly with global climate initiatives, where sustainable sourcing and energy-efficient production are becoming standard rather than exceptional.

Applications that define innovation

One of the most significant changes in recent years is the integration of advanced metals into consumer and industrial products. From electric vehicle frames and drones to medical devices and renewable energy components, material innovation is shaping the future of manufacturing. Lightweight metals enable intricate designs without sacrificing performance, making them essential for engineers who seek precision and reliability.

In fabrication processes, aluminium tubing has proven to be particularly effective for achieving both durability and weight reduction. It’s a preferred choice across numerous industries, offering excellent corrosion resistance and versatility in form. Whether in architectural frameworks, transport systems, or industrial machinery, its adaptability makes it invaluable for designers who need performance and practicality in equal measure.

Technological advancement in production

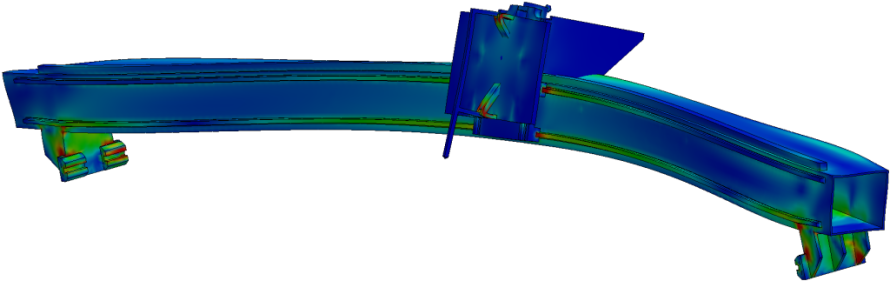

The manufacturing landscape has also evolved with the rise of computer-aided design (CAD) and automation. These technologies allow for exacting tolerances, waste minimization, and consistency across production lines. Manufacturers can now develop complex shapes and structures that were once cost-prohibitive or impossible to produce. Techniques like extrusion, precision cutting, and surface finishing have elevated the quality of components to new levels of accuracy and reliability.

Furthermore, digital twin technology enables engineers to simulate and test material performance before any physical prototype is created. This reduces development cycles and ensures that design flaws are identified early, saving both time and resources.

Challenges and opportunities

Despite these advancements, the industry faces challenges such as rising raw material costs, energy consumption, and the need for skilled labor. However, these issues are counterbalanced by innovation in energy-efficient furnaces, closed-loop recycling systems, and global supply chain optimization. As the demand for precision-engineered products increases, manufacturers that can balance cost, sustainability, and performance will have a competitive advantage.

Looking to the future

The next decade will likely see even more advanced alloys, hybrid materials, and smart fabrication methods. Nanotechnology and additive manufacturing are already making an impact, allowing for lighter yet stronger materials that respond dynamically to stress and temperature. These innovations will redefine what’s possible in product design and open up entirely new markets for industries that depend on structural integrity and efficiency.

In summary, the pursuit of lightweight precision has redefined the boundaries of modern engineering. By combining strength, sustainability, and adaptability, industries are laying the groundwork for a future where materials not only support innovation but also drive it.